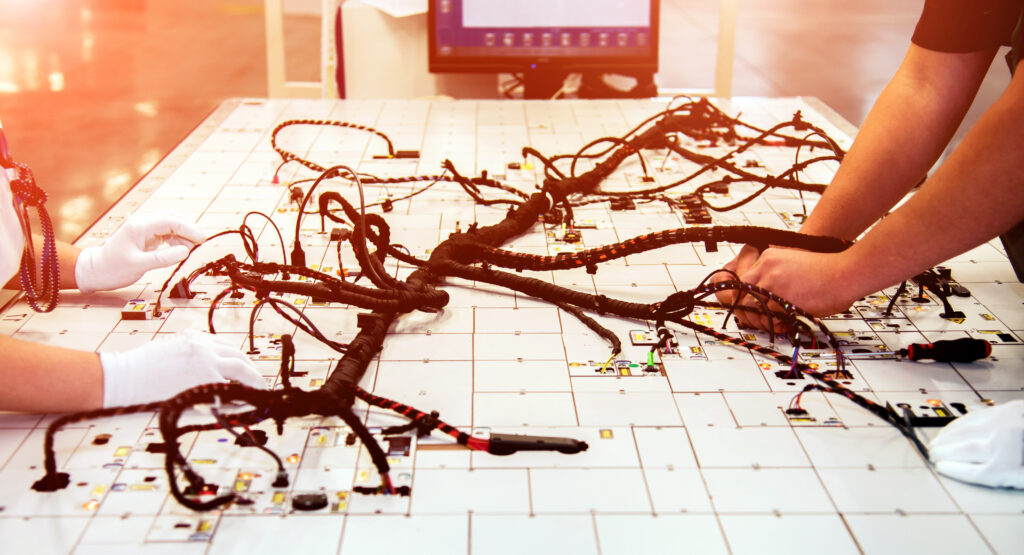

Since 2001, Aeromotive has specialized in delivering high-quality, low-volume wire harness assemblies built to exact specifications. Whether it’s a single prototype or a 5,000-unit run, our Build-to-Print process ensures precision without compromise.

Prototyping: Engineering Validation at Every Step

Every successful build starts with rigorous prototyping. Our dedicated team collaborates with engineering to ensure:

- Cable lengths are validated for accurate fitment

- Material compatibility is confirmed

- Bill of Materials (BOM) verification prevents inconsistencies

- Quality control testing ensures product reliability

- Engineering Change Orders (ECOs) are managed efficiently

Collaboration between our engineering and prototyping teams ensures that every unit meets design intent, manufacturing feasibility, and quality expectations before moving into production.

Production: Built for Reliability

Once a prototype is validated, we move into first article builds, giving customers an opportunity to review and refine before full production. Our quality-driven process includes:

- PPAP and Control Plan execution to standardize quality

- On-floor quality control to monitor production

- Advanced testing protocols, including pull, continuity, and 300x microscopic inspections

Cradle-to-Grave: Sustainability & Remanufacturing

At Aeromotive, we don’t just build for today—we plan for the entire lifecycle of your wire harness or wiring harness assembly. Our remanufacturing program extends the life of aging wire harnesses, providing cost-effective, sustainable solutions.

Whether you need prototyping, production, or lifecycle management, Aeromotive delivers quality without compromise.

Have a project in mind? Let’s build it together. Contact Us →

Meet Aeromotive at Work Truck Week 2025

We’ll be at booth 544 during Work Truck Week, showcasing our latest advancements in wire harness technology and fleet optimization. If you’re looking to improve efficiency, enhance durability, and minimize downtime, let’s connect. Learn more about WTW25 here!

📅 Schedule a meeting or stop by booth 544 to learn more.

Additionally, if you’re attending AASP-IL, don’t miss Carl’s presentation on evaluating wire damage on February 22nd. It’s a great opportunity to connect with us about how our solutions support fleet optimization.